Hot runner systems

Reliable technology for standard applications.

A brand from

Simple handling

Install, connect and get started

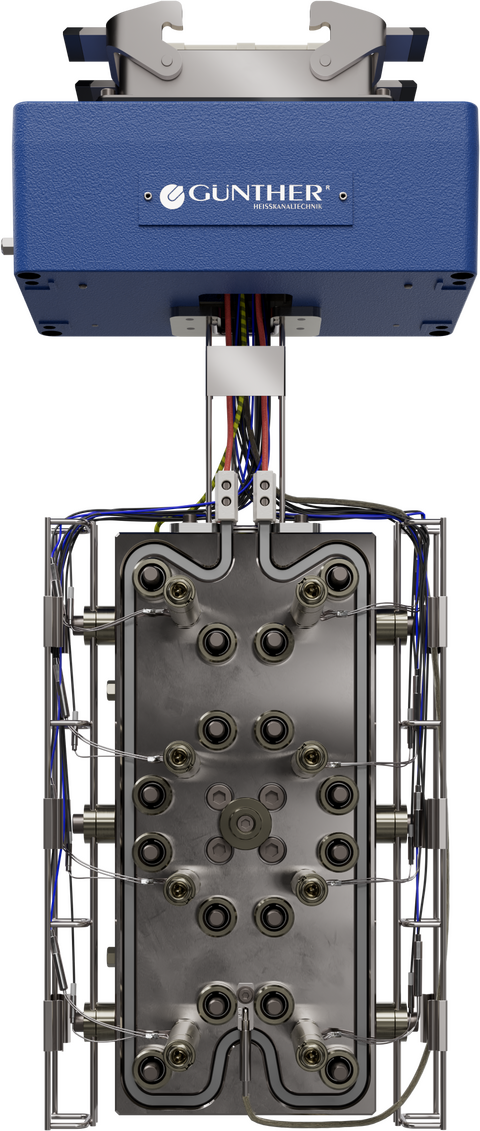

Our hot runner system offers maximum efficiency at an affordable price. The low hot runner height reduces the mold height and the tool opening can be used optimally.

The Basic Line systems are designed for processing simple plastics and also enable the processing of filled plastics with a filling level of up to 15 percent.

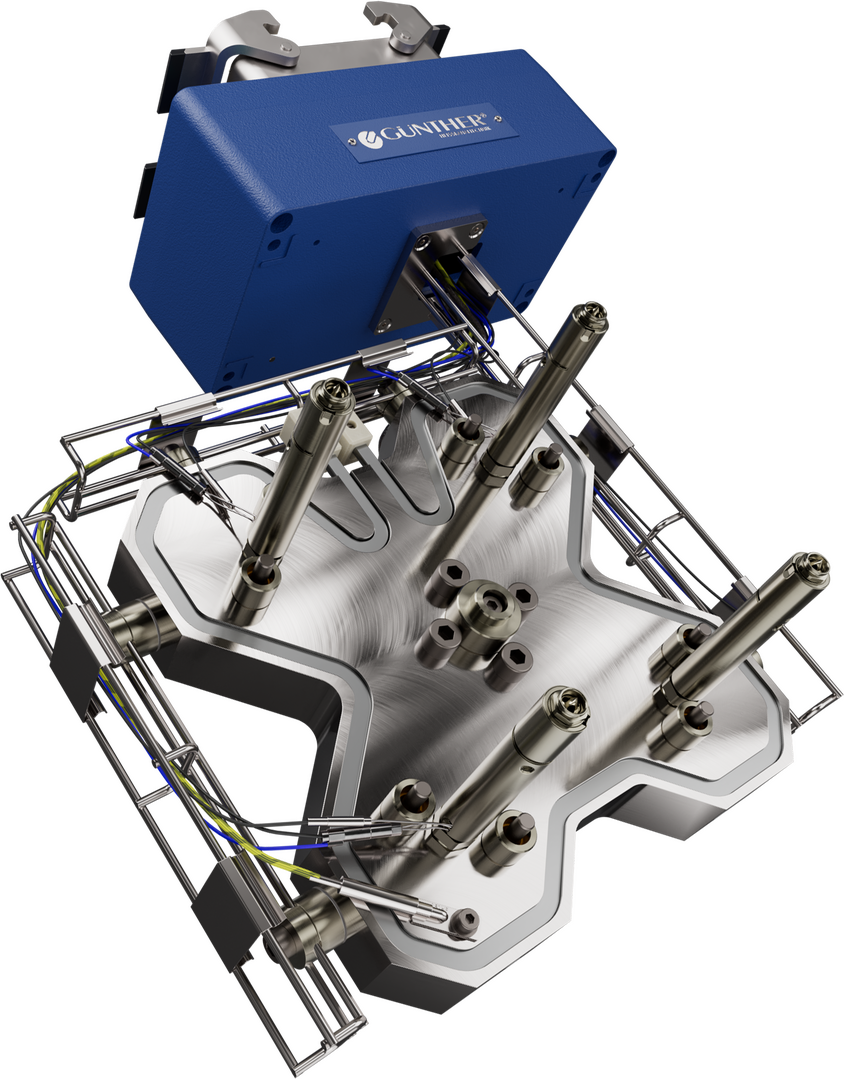

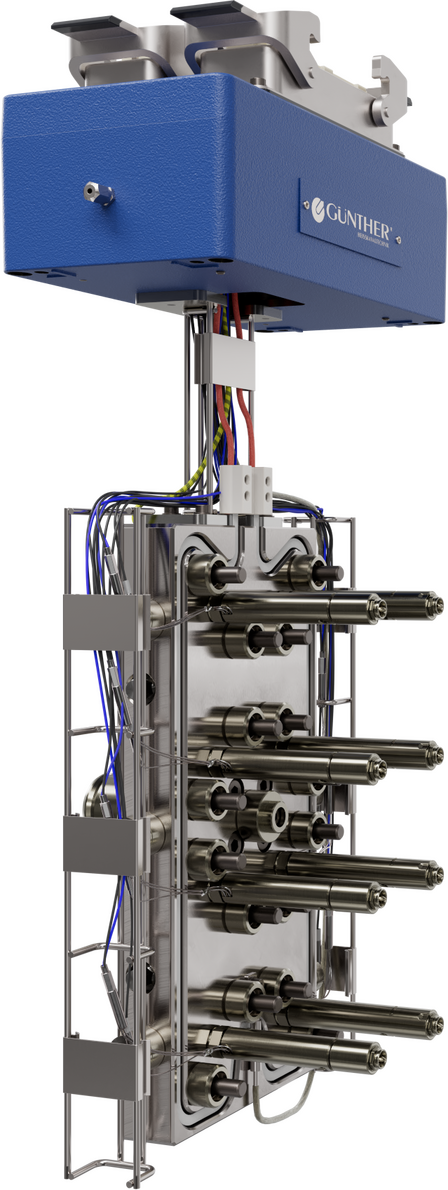

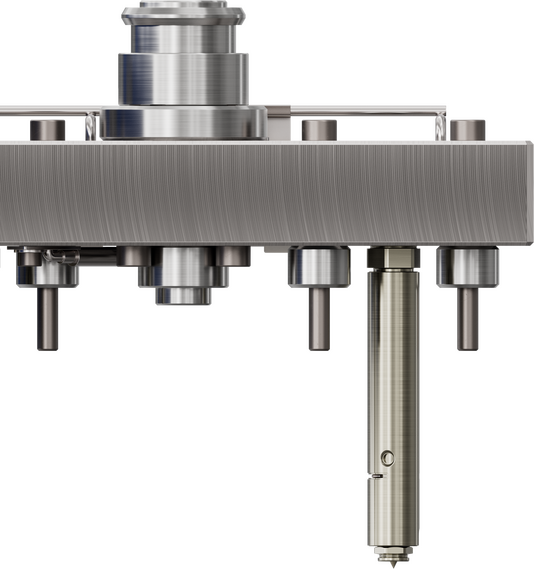

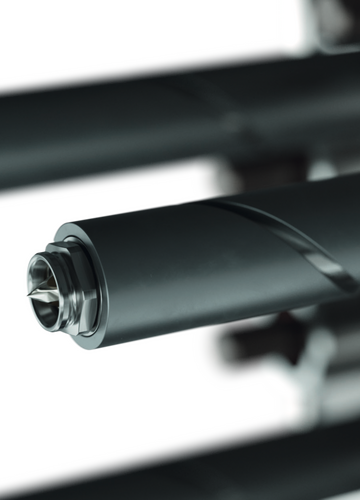

The hot runner nozzles are equipped with a fixed power connection and a fixed thermal connection. The nozzle sizes are available in standard versions with melt channel diameters of 6 and 10 mm and lengths of 80, 120 and 150 mm. The Basic2Connect system is suitable for a wide range of standard materials. Maximum temperatures for service and installation work are taken into account in the design and layout of the heating elements.

Your benefits:

- System nozzles with removeable heaters

- Melt channel diameters of 6 and 10 mm

- Nozzle lengths from 80, 120 and 150 mm

- Compact and cost saving design

- Durable and easy to maintain construction

- Processing of materials with up to 15 % filling

Homogeneous melt channel temperature

Our hot runner system impresses with its homogeneous temperatures in the melt channel, which ensures uniform processing and optimum product quality. With a high level of process reliability, our Basic Line systems ensure stable and reproducible production processes - ideal for applications with plastics from the lower to middle area of the performance pyramid.

Rely on efficiency and precision in plastics processing.

We offer high-quality systems with state-of-the-art technology and maximum efficiency for applications with high requirements.

Your application at a glance

Basic2Connect is wired and ready for installation, which makes it easy to install and remove. It makes handling even more user-friendly.

“The Basic Line systems are specially designed for processing standard plastics.”

Processing of materials

with up to 15 % filling

Channel diameter

- ø 6 mm

- ø 10 mm

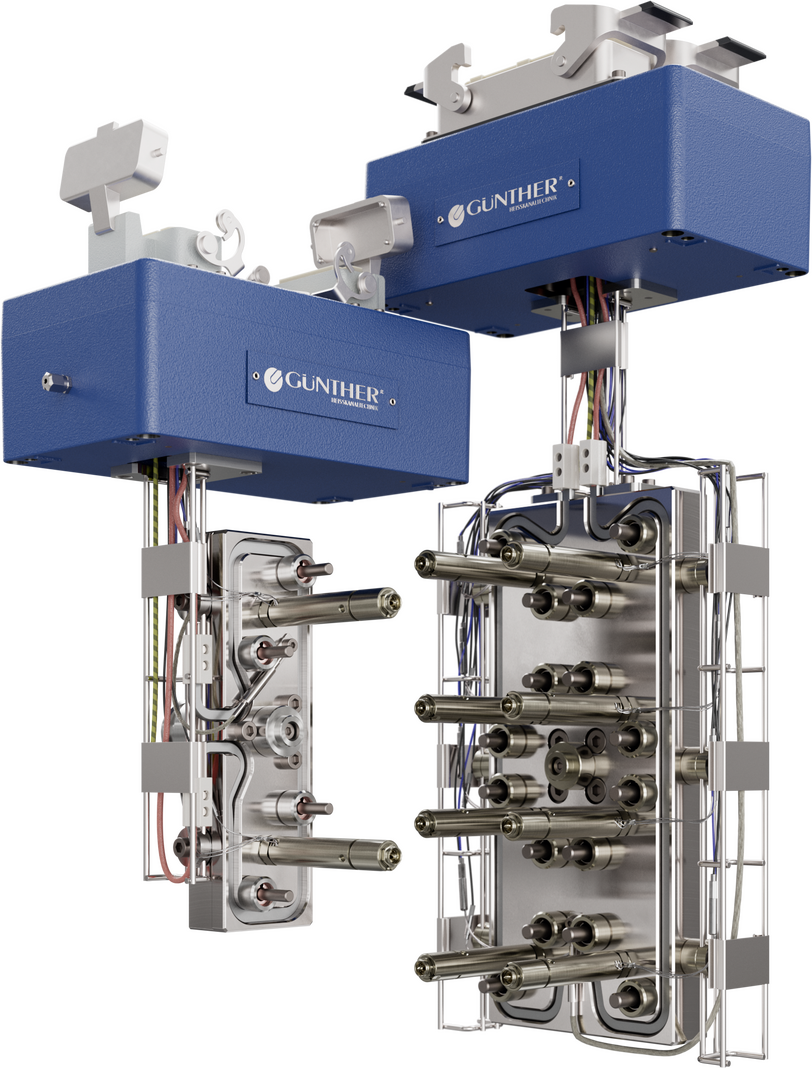

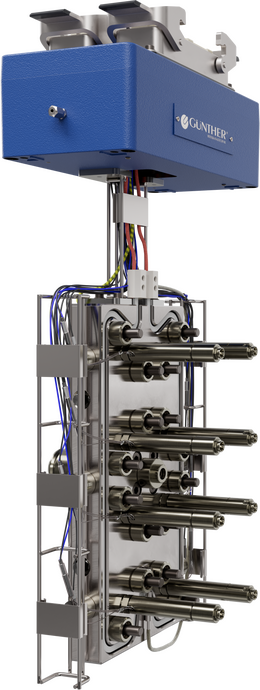

Basic2Connect

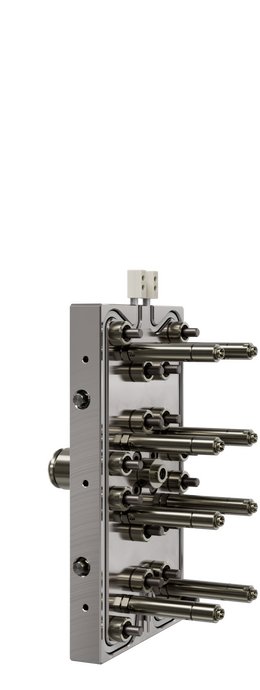

- Manifold

- Nozzles

- Cable channel and cable box with housings

- Fully assembled, wired and electrically checked

Basic

- Manifold

- Nozzles

Nozzle length depending on pitches

Nozzle length

80 mm, 120 mm, 150 mm

A brand from

GÜNTHER Heisskanaltechnik GmbH

Industriepark Nord

Sachsenberger Strasse 1

35066 Frankenberg (Eder)

Germany

P +49 6451 5008 - 0

info@guenther-heisskanal.de

www.guenther-hotrunner.com